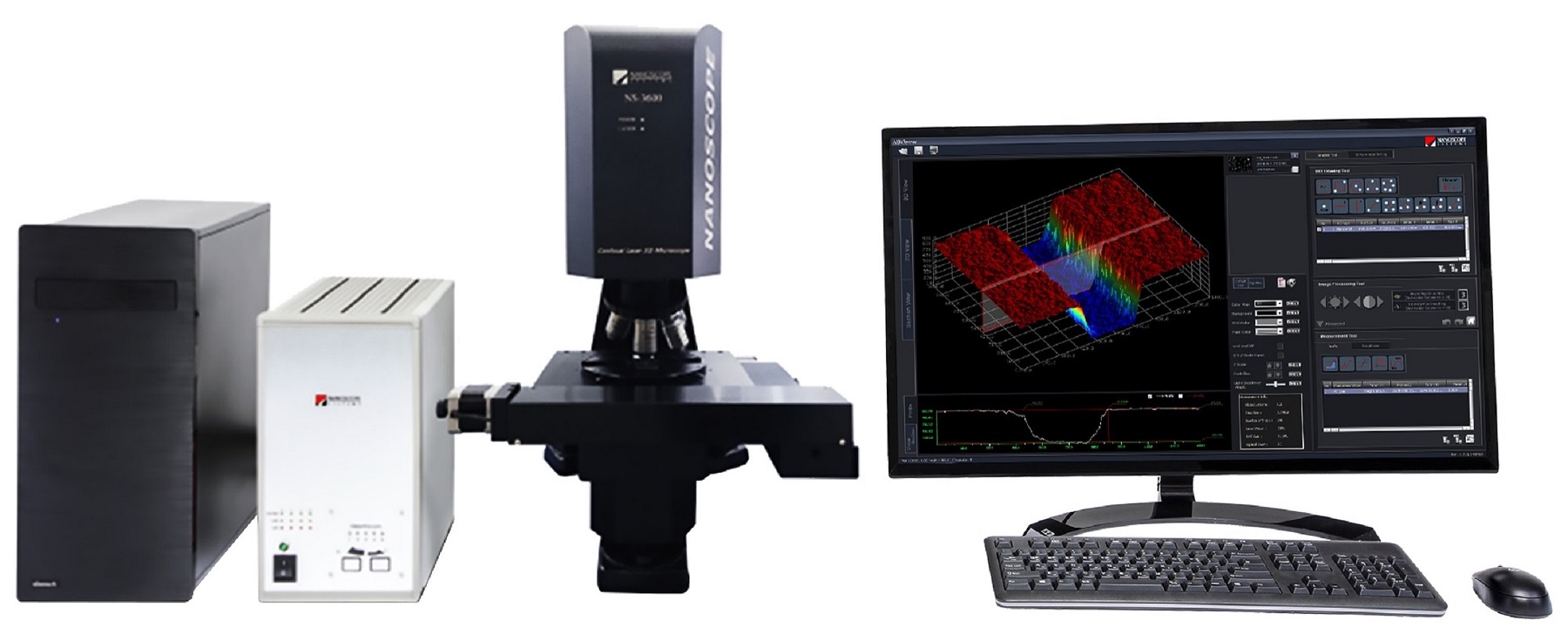

Overview of NS-3500 Technology

The NS-3500 represents a breakthrough in optical metrology. It utilizes the Confocal principle, the most reliable non-contact inspection method available today. Unlike conventional microscopes, the NS-3500 provides sharp 3D images by filtering out-of-focus light, making it ideal for challenging samples like glass, thin films, and semiconductor wafers.

Key Features and Advantages

-

High-Resolution 3D Metrology: Accurate, non-destructive measurement of micro-structures.

-

Real-time Confocal Imaging: Instant visual feedback with rapid focusing capabilities.

-

Surface Roughness Analysis: Automated measurement of optical roughness parameters (ISO compliant).

-

Dual Observation Mode: Simultaneous viewing of 2D microscopic images and 3D confocal data.

-

Auto Tilt Correction: Advanced algorithms to compensate for sample misalignment.

-

Large Area Stitching (NSMosaic): Automatically scan and combine multiple high-magnification images into a single wide-field 3D map.

-

Zero Sample Preparation: No coating or vacuum required, saving time compared to SEM or AFM.

Technical Specifications

| Feature | Specification |

|---|---|

| Laser Source | Laser Diode (Standard 405nm) |

| Z-axis Resolution | Display resolution up to 1nm |

| Scanning System | High-speed Galvano Scanner |

| Stage Type | Motorized XY Stage (Options: 50mm, 100mm, 150mm) |

| Objective Lenses | 5x to 100x (High NA Confocal Objectives) |

| Software Suite | NSWorks (Operation), NSViewer (Analysis), NSMosaic (Stitching) |

Industrial Applications

-

Semiconductor: IC pattern measurement, Bump height, Wire loop inspection, and CMP process analysis.

-

FPD (Flat Panel Display): Touch panel inspection, ITO pattern measurement, and LCD column spacer height.

-

MEMS Devices: 3D profiling of micro-electro-mechanical systems and surface roughness inspection.

-

Materials Science: Tool surface inspection, crack analysis, and solar cell texture measurement.

Frequently Asked Questions (FAQ)

-

Can the NS-3500 measure transparent materials?

Yes. The confocal optical system effectively filters internal reflections, allowing precise 3D reconstruction of glass, polymers, and transparent films.

-

How does NS-3500 differ from an AFM?

While AFM uses a physical probe (contact), the NS-3500 uses a Laser (non-contact). This allows for much faster scanning speeds and eliminates the risk of damaging sensitive samples.

-

Is sample coating required?

No. Unlike SEM, the NS-3500 does not require gold coating or a vacuum environment. You can measure samples in their natural state.

Related Video / Webinar

- Webinar: -

- Video: -

English (UK)

English (UK)  日本語 (Japan)

日本語 (Japan)  한국어 (Korean)

한국어 (Korean)  Tiếng Việt

Tiếng Việt  中文 (Chinese)

中文 (Chinese)